Unlocking the Power of China Lathe Machine CNC Turning Parts in Modern Metal Fabrication

In the dynamic world of metal fabrication, precision, efficiency, and innovation are the cornerstones of success. Among the multitude of machinery used in manufacturing, lathe machines—especially those sourced from China—stand out for their remarkable versatility and cost-effectiveness. Specifically, china lathe machine cnc turning parts have revolutionized the way industries produce complex metal components, offering unmatched accuracy and repeatability.

Understanding the Role of China Lathe Machine CNC Turning Parts in Metal Fabrication

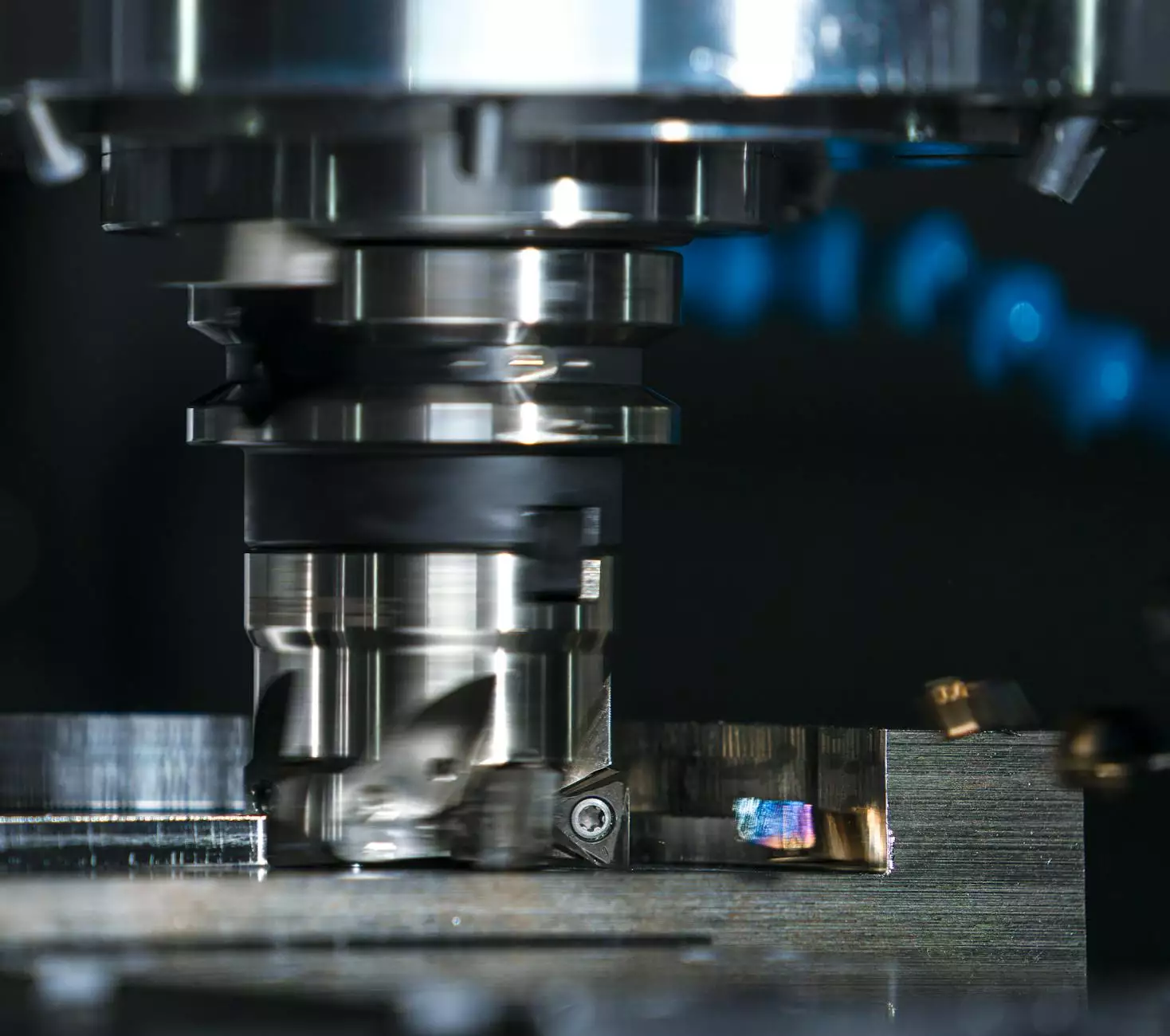

China lathe machine CNC turning parts refer to the precision-engineered components used in CNC (Computer Numerical Control) lathes manufactured in China. These parts include a variety of critical elements such as spindles, tool holders, chucks, guideways, and cutting tools, all designed to work seamlessly in high-speed, automated machining environments.

With advances in manufacturing technology, Chinese suppliers have emerged as global leaders in producing high-quality CNC turning parts that meet international standards. This is driven by their dedication to innovation, investment in modern machinery, and adherence to rigorous quality control processes.

The Advantages of Using China Lathe Machine CNC Turning Parts in Your Business

1. Superior Precision and Tight Tolerance Control

One of the primary benefits of china lathe machine cnc turning parts is their exceptional precision. Advanced CNC technology allows for manufacturing components with minimal tolerances—often within micrometers. This level of accuracy ensures that components fit perfectly, reducing assembly issues and enhancing overall product quality.

2. Cost-Effectiveness without Compromising Quality

Chinese manufacturers leverage economies of scale and innovative production methods to deliver CNC turning parts at competitive prices. Businesses benefit from significant cost savings, especially when scaling production, while still receiving products that adhere to strict quality standards. This cost efficiency makes Chinese lathe machine components an attractive choice for startups and established manufacturing firms alike.

3. Customization and Versatility

The capacity for customization is a cardinal feature of Chinese CNC turning parts. Leading suppliers can produce tailored components based on detailed specifications, enabling the manufacturing of complex geometries and unique designs. This flexibility allows businesses to innovate and diversify their product offerings effectively.

4. Reliability and Durability

Quality Chinese lathe machine CNC turning parts are constructed from durable materials such as alloy steels, high-grade aluminum, and hardened steels that withstand rigorous operational conditions. This durability translates to longer service life, reduced downtime, and lower maintenance costs for your equipment.

5. Rapid Turnaround and Supply Chain Efficiency

Manufacturers in China emphasize fast production cycles and efficient logistics, ensuring that your orders are fulfilled promptly. Many suppliers also offer warehousing options to maintain ready stock, enabling just-in-time manufacturing and minimizing delays in your production pipeline.

Application Domains for China Lathe Machine CNC Turning Parts

These precision components serve a wide array of industries, including but not limited to:

- Automotive Manufacturing: Creating engine components, transmission parts, and chassis elements.

- Aerospace: Producing high-precision parts for aircraft and spacecraft.

- Electronics: Manufacturing enclosures, connectors, and intricate mechanical components.

- Medical Equipment: Crafting surgical tools, implants, and diagnostic devices.

- Energy Sector: Fabricating parts for turbines, generators, and oil & gas machinery.

Choosing the Right Supplier for CNC Turning Parts in China

Key Criteria for Selection

- Certifications and Standards: Ensure suppliers follow ISO 9001 or equivalent quality certifications.

- Production Capabilities: Verify their capacity to handle complex or large-volume orders.

- Material Options: Confirm they can supply the appropriate raw materials for your application.

- Customization Services: Assess their ability to customize parts according to your specifications.

- Quality Control Protocols: Look for rigorous testing and inspection processes to guarantee part accuracy and reliability.

- Customer Support and Communication: Choose suppliers who offer transparent communication and dedicated support services.

Deepmould.net: Your Trusted Partner for Chinese CNC Turning Parts

As a leading metal fabricator specializing in high-precision china lathe machine CNC turning parts, deepmould.net leverages decades of manufacturing expertise, advanced CNC technology, and a customer-centric approach to deliver top-tier solutions. Their commitment to quality, cost-efficiency, and timely delivery makes them a preferred partner for global businesses seeking reliable Chinese parts.

Why Collaborate with Deepmould.net?

- Comprehensive Customization: Tailor-made parts designed to your unique specifications.

- Rigorous Quality Assurance: Stringent inspection processes to ensure each component meets international standards.

- Competitive Pricing: Cost-effective solutions without sacrificing quality.

- Fast Lead Times: Efficient production and logistics to meet your project deadlines.

- Global Logistics Support: Reliable shipping options for worldwide delivery.

- Technical Expertise: Experienced engineers ready to consult on material choice, design optimization, and more.

Future Trends in Chinese CNC Turning Components for the Metal Fabrication Industry

Looking forward, the industry is poised for transformative advancements, including:

- Automation and Smart Manufacturing: Increased adoption of AI and IoT-enabled machinery for real-time monitoring and adaptive machining.

- Material Innovation: Development of high-performance composites and advanced alloys for specialized applications.

- Enhanced Sustainability: Focus on eco-friendly manufacturing processes and recyclable materials.

- Integration of Additive Manufacturing: Combining CNC turning with 3D printing for complex component fabrication.

Conclusion: Investing in Quality China Lathe Machine CNC Turning Parts for Business Growth

In the competitive landscape of metal fabrication, leveraging the best china lathe machine CNC turning parts can dramatically enhance your operational efficiency, product quality, and cost management. Partnering with reputable manufacturers like deepmould.net ensures access to reliable, high-precision components tailored to your unique needs. Embracing these advanced manufacturing solutions positions your business for sustainable growth and continued success in an industry that thrives on innovation and excellence.

Invest in quality, precision, and strategic partnership today, and unlock the full potential of your metal fabrication projects with China’s leading CNC turning part solutions.